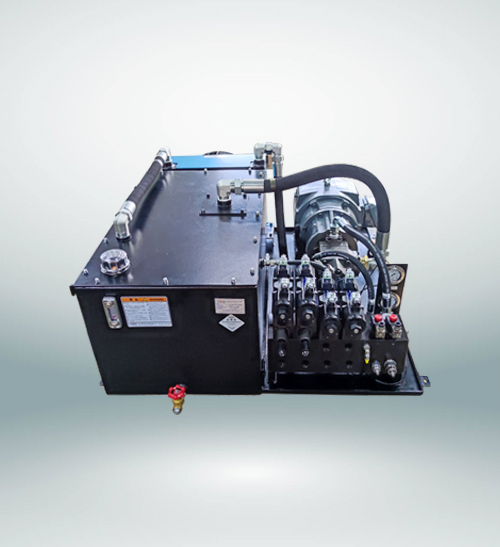

Principle: achieve the purpose of dehydration through vacuum suction. The slurry is sent to the filter cloth of vacuum belt dehydrator. The filter cloth is carried by a thick rubber belt. There are transverse grooves and through-hole in the center of the tape to suck liquid into the vacuum tank. The filtrate and air are simultaneously pumped to the vacuum header. The filtrate in the vacuum filtrate collection pipe enters the gas-liquid separator for gas-liquid separation. The top outlet of the gas-liquid separator is connected with the vacuum pump to extract gas from the vacuum pump. The separated filtrate enters the filtrate receiving water tank from the outlet at the bottom of the gas-liquid separator. The slurry is vacuumized in the forming area, washing area and monotonous area to form qualified filter cake, which is sent to the unloading tank in the unloading area and then sent to the gypsum warehouse by the conveyor belt. Vacuum belt dehydrator is also called fixed vacuum chamber rubber belt filter. It is a new, efficient and continuous solid-liquid separation mechanical equipment developed on the basis of the introduction, digestion and absorption of foreign similar products and technologies. It is also a mechanical equipment that makes full use of the gravity and vacuum suction of materials to complete solid-liquid separation. In structure, the vacuum area is horizontally arranged, and different technological processes such as filtration, washing and monotony can be continuously completed by using the length of the vacuum area. The utility model has the advantages of high filtering effect, large raw material production capacity, good washing effect, wide application scope, simple operation, stable operation, convenient maintenance, etc; It is especially suitable for large diameter filtration, with dense solid particles and high requirements for filter cake. The secondary washing slurry can be widely used in metallurgical, mining, chemical, paper making, food and other solid-liquid operations, pharmaceutical, environmental protection and other operations. In particular, the desulfurization gypsum dehydration hydraulic motor is a device that converts the pressure energy of liquid into mechanical energy. In principle, the hydraulic pump can be used as a hydraulic motor.

The structural differences between pump and hydraulic motor are introduced as follows:

1. The hydraulic motor needs forward rotation, and the structure should be symmetrical, but the hydraulic pump rotates in one direction;

2. Low stable speed is an important index of hydraulic motor;

The low pressure chamber pressure of three hydraulic pumps is generally vacuum. In order to improve the oil absorption function and turbidity resistance, the oil inlet is generally larger than the oil outlet, and the pressure in the oil return chamber of the hydraulic motor is slightly higher than the atmospheric pressure;

4. The hydraulic pump needs self-priming capacity, while the hydraulic motor does not;

5. For example, the axial compensation coefficient of the gear hydraulic motor is far less than that of the pump to reduce friction.

Operating characteristics of hydraulic motor:

1. The hydraulic motor shall be able to operate back and forth. Therefore, the hydraulic motor is required to be symmetrical in design;

2. Under normal working conditions, the inlet and outlet pressure of the hydraulic motor is higher than the atmospheric pressure, so the hydraulic pump has no suction function problem. However, if the hydraulic motor can work under the working condition of the pump, the oil inlet of the hydraulic motor should have a low pressure limit to avoid the occurrence of steam turbidity;

3. The actual operating differential pressure of the hydraulic motor depends on the size of the load. When the driven load has a large moment of inertia and high speed, and requires rapid braking or rotation, high hydraulic impact will occur. Therefore, a buffer valve - river valve should be set in the system;

4. Some types of hydraulic motors have enough back pressure at the oil return port to ensure the normal operation of the hydraulic motor;

5. Due to inevitable internal leakage, when the oil drain of the motor is closed for braking, there is still slow slipping. Therefore, when long-term accurate braking is required, a separate brake shall be set to prevent slipping.